SCREENING OF RECYCLED AGGREGATES

Optimize Your Resources with Filtra Vibración

The screening of recycled aggregates is a key step in turning construction and demolition waste into valuable raw materials. This process allows for the separation and classification of concrete, asphalt, brick, glass, or slag fragments into homogeneous fractions. These fractions meet the required particle size and cleanliness standards for use in concrete mixes, pavement bases, and controlled fills.

Initial Processing and Classification

The process starts with the crushing of leftover concrete or demolition waste. Once fragmented, the material is sorted into two main groups:

-

Fine aggregate, composed of smaller particles.

-

Coarse aggregate, consisting of larger fragments.

Since recycled material often includes impurities like embedded steel, plastic, or glass, initial cleaning is essential to ensure a consistent and safe final product.

Contaminant Removal

Before screening, non-concrete elements such as asphalt, bricks, joint sealants, wood, or other materials must be removed. This step is crucial to guarantee the quality and performance of the recycled aggregate in new applications.

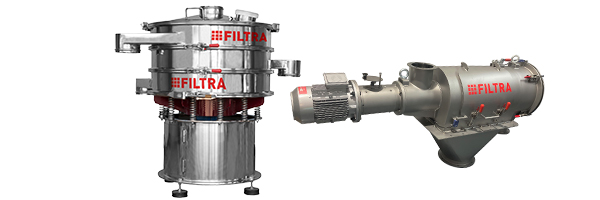

Screening with Filtra Vibración Equipment

At Filtra Vibración, our screening equipment is built to handle the specific challenges of recycled materials:

-

Interchangeable mesh screens

-

Fine meshes remove dust and adhered particles.

-

Wider openings allow separation of coarser fractions.

-

Quick mesh changes without tools reduce downtime.

-

-

Uniform vibration system

-

Prevents clogging and material buildup.

-

Ensures consistent material flow across the screen.

-

-

Continuous cleaning systems

-

Equipped with rings or vibrating balls.

-

Prevent mesh blockages and maintain performance.

-

Ensure uninterrupted material processing.

-

Flexible Installation Options

Our equipment adapts to various plant layouts and production needs:

-

Self-supporting frames: no civil works required.

-

Mobile units: easy relocation within the plant.

-

ATEX-certified models: for use in potentially explosive environments.

Additional Benefits

Beyond precision screening, Filtra Vibración’s solutions provide:

-

Simplified maintenance, thanks to accessible design.

-

Scalability, allowing multiple screens in series or parallel.

-

Cost savings, by reducing waste sent to landfill.

-

Regulatory compliance, ensuring the required particle size distribution is achieved.

Contact us for personalized advice and discover how to improve your recycled aggregate process with our screening technology.