SIFTING OF DEHYDRATED TOMATO

The sifting process of dehydrated tomato is a crucial stage in the production of this versatile and long-lasting ingredient. Starting with fresh and ripe tomatoes, the first step involves the careful selection of raw materials to ensure the quality of the final product.

Once harvested, the tomatoes undergo a dehydration process, which involves removing the water content through methods such as sun drying or the use of industrial dehydrators.

After dehydration, the tomatoes take on a more compact and concentrated form, but to achieve the desired texture and purity, sifting is essential. This process is carried out using sieves of different sizes that allow the separation of larger pieces from the pulp and skin, resulting in a uniform and high-quality final product. Sifting not only eliminates impurities but also helps achieve a fine and homogeneous texture.

In the specific case of dehydrated tomatoes, sifting can be done in multiple stages, with sieves of various openings to separate different fractions of the product. The first phase may remove larger pieces, such as skin or seeds, while subsequent stages can further refine the texture of the dehydrated tomato. This process ensures that the final product meets the quality standards and specific requirements of the food industry.

The importance of sifting in the production of dehydrated tomatoes lies in its ability to enhance the consistency and quality of the product, as well as to meet food safety standards by eliminating any unwanted materials. From sauces to soups and dressings, sifted dehydrated tomatoes become a valuable ingredient in the kitchen, providing concentrated flavor and versatility to a variety of culinary preparations.

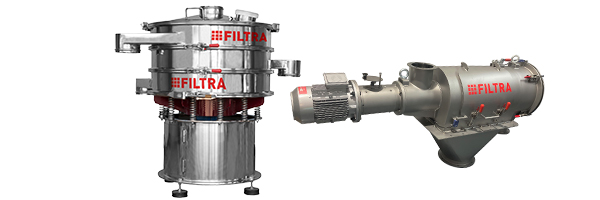

Filtra Vibración offers the best solutions for the type of sifting required in your product. Our equipment adapts and optimizes the sifting process to achieve the desired results.

Contact our experts, and they will help you find the best solutions in filtration and sifting.