CANDY SIEVING

CANDY SIEVING

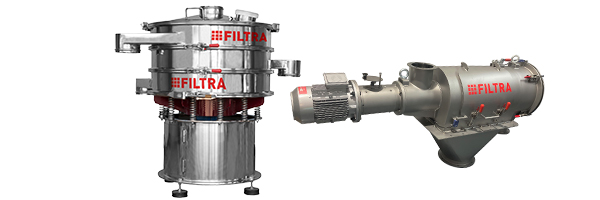

SIEVING TEST ON CANDY USING IRIS EQUIPMENT:

PRECISE PARTICLE SIZE CONTROL

In the analysis of candy fragments, the sieving test is essential for characterizing particle size and ensuring consistency in the final product.

What does sieving with the IRIS equipment allow you to evaluate?

Accurate particle size distribution for controlled formulations.

Efficient separation of out-of-spec particles.

Comparable data to standardize batches and adjust production parameters.

This type of analysis is fundamental in quality and development laboratories, especially when aiming to:

Optimize blends of crushed candies or toppings.

Evaluate the impact of grinding or fragmentation processes.

Validate technical requirements for automated production lines.

Advantages of the IRIS Equipment in Candy Sieving

The IRIS equipment enables fast and reproducible sieving, making it ideal for tests in accordance with standardized norms in the food and confectionery industries.

In addition, performing a sieving test with the IRIS equipment helps reduce raw material waste, improve operational efficiency, and ensure a consistent experience for the end consumer.

For sensitive products like crushed candies, particle size control not only affects appearance but also influences perceived quality and product stability during storage or transportation.

This type of analysis is also useful for developing more accurate technical data sheets, meeting export requirements, or designing specific formulations for different markets.

For a general guide on the principles of particle size analysis in food, you can consult online technical resources such as this one on sieving.

Do you carry out quality control in confectionery or develop new candy-based products?

Contact us: filtra@filtra.com