APOLO – SACK TIP STATION

APOLO – SACK TIP STATION

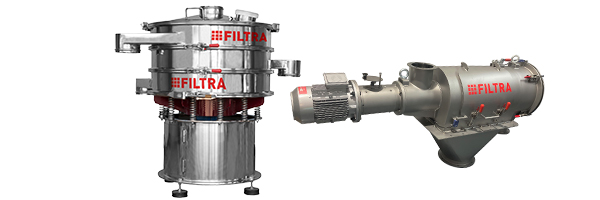

In order to facilitate a safe handling for raw materials delivered in all types of bags, FILTRA has developed the APOLO series (Sack Tip Station). Its design prevents particle spreading within the environment, safeguarding the operator from dust surroundings. Its low profile allow the worker to handle it healthy and safely.

BENEFITS:

- Bag Dump Screener available in two capacities

- Dust Cabinet

- Easy to clean

- Exchangeable sieves

- Reduces material losses

- Low maintenance

INCLUDES:

- Screener with central electric vibrator

- Steerable Dust Cabinet, see options

- Bag Tip Table

- User Manual

- CE declaration of conformity

ATEX:

If the sieve shaker is going to be used in areas classified as being potentially explosive environments then it is manufactured with ATEX materials, and FILTRA will supply the corresponding ATEX certificate.

Available for 800 mm diameter.

| Model | Voltage (V) | r.p.m | Power (kW) | Weight (Kg) |

|---|---|---|---|---|

| VSIS-800 | 380-400 | 1500/1800 | 0.3 | 177,5 |

Magnetic filters are suitable for the separation of small iron particles.

As for the magnetic grids, they are used for the purification of any particle contained in dusty or granulated products, either in dry or wet. Therefore, they are specially designed and adapted for the food industry, ceramics, plastics, etc…

The grids and semi-suction filters are used in any production process where contamination by metal particles is abundant or simply a continuous cleaning is necessary.

These filters have a polished stainless steel finish (AISI 304 or AISI 316) which assures a high resistance to rust and wear.