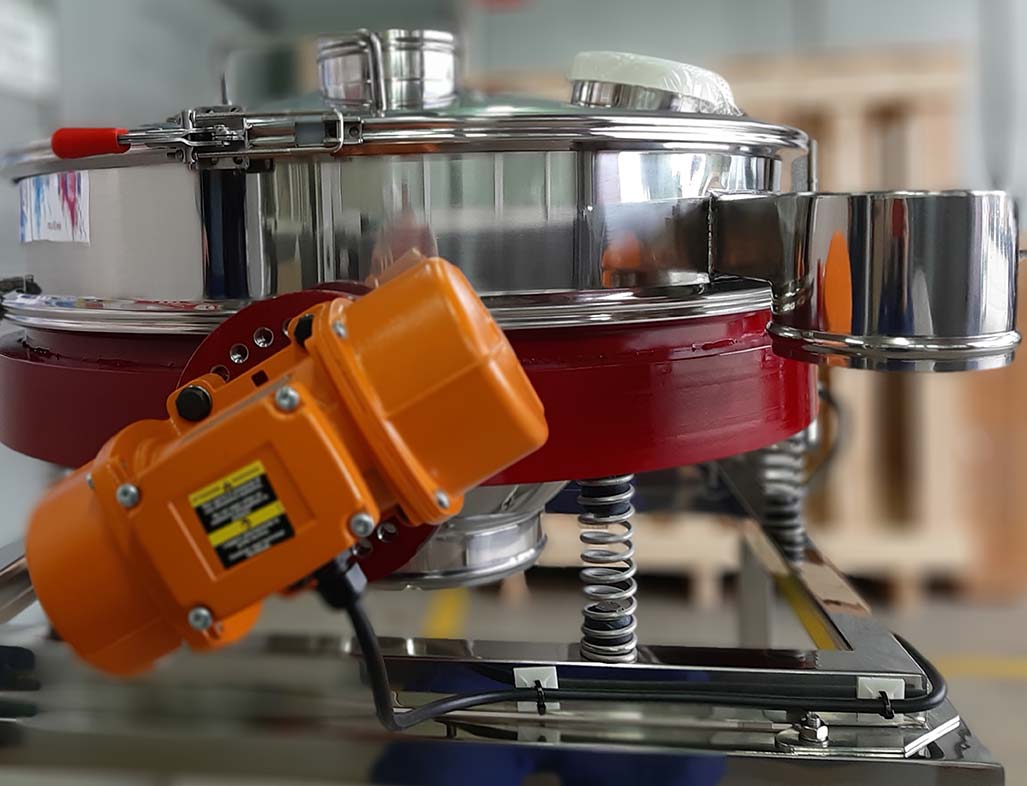

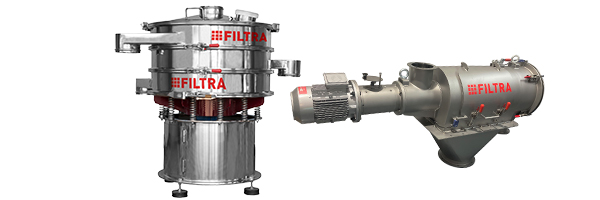

HELIOS – SIDE MOTORS CIRCULAR SIEVE SHAKER

HELIOS – SIDE MOTORS CIRCULAR SIEVE SHAKER

The Helios Circular Sieve Shaker is especially recommended for control and safety sieving for both solids and liquids. It is very useful in confined spaces where the reception of material and the unloading of the sieved product are in close proximity. It permits a large product volume and a single sieving level.

AVANTAGE:

- Extremely robust and reliable. It can work 24 hours a day.

- It occupies little space.

- It allows for a large product volume.

- Central loading and unloading of material.

- Low maintenance.

ATEX:

If the sieve shaker is going to be used in areas classified as being potentially explosive environments then it is manufactured with ATEX materials, and FILTRA will supply the corresponding ATEX certificate.

Available in three diameters: 550, 800 and 1200 mm.

| TECHNICAL FEATURES | ||||||

| Model | Voltage (V) | Freq. (Hz) | r.p.m | (A) | Power (kW) | Weight (Kg) |

| FTI-2M-0550 | 400/460 | 50/60 (3F) |

1500 | 0,41 | 0,17 | 87 |

| FTI-2M-0800 | 0,41 | 0,17 | 110 | |||

| FTI-2M-1200 | 0,6 | 0,3 | 210 | |||

Customized execution for special customer.

Bench for Helios.

- Chemical

- Agricultural

- Food

- Pharmaceutical

- Seeds

- Paints

- Resins

- Glass

- Waste water

- Plastic