ATENEA – INDUSTRIAL V-MIXER

ATENEA – INDUSTRIAL V-MIXER

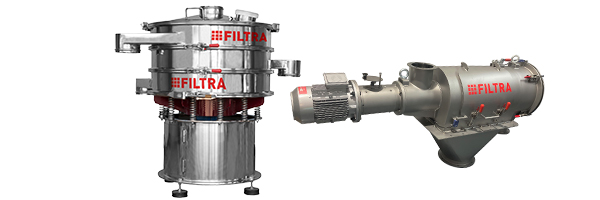

The ATENEA Industrial V-Mixer is used to achieve perfect homogenization of solid with solid (in any proportion) and solid with liquid (10% maximum) products in powder or granulated form.

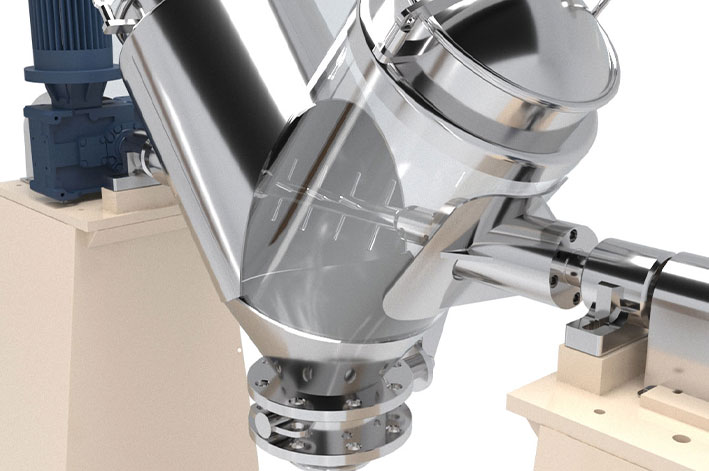

It has a V-shaped body made of AISI-316 stainless steel, with two loading inlets and one outlet, with a butterfly valve to facilitate the unloading of the mixture.

Due to the V-shape axial currents are produced when the body is turned through 360º, and these currents separate and unite the product to be mixed. This, along with the radial mixing action, produces an extremely homogeneous result (in the proportion of 1 part in 10.000).

BENEFITS:

- It allows for smooth mixing without deformation to the particles or, when necessary, energetic mixing in order to break up lumps with the intensifying bar.

- Complete unloading through gravity. The receptacles are designed to prevent product sediment accumulating in their interior, which is free of angles, corners or grooves.

- A minimum of environmental contamination during mixing time, as it is has inlets and outlets with hermetically sealing caps. V-shaped receptacle.

- Compact design.

- Low energy consumption when compared to other mixing systems.

- Easy to operate.

- Easy to clean, as its interior is highly polished and is free of angles.

- Highly cost-effective due to its mixing quality and low maintenance.

- Touch screen and low maintenance.

- Very low installation and assembly costs, as the mixers leave our workshop ready for use.

INCLUDES:

- The V-shaped receptacle is mirror-polished, both inside and outside.

- Two easy-opening hermetic loading inlets with EPDM seals.

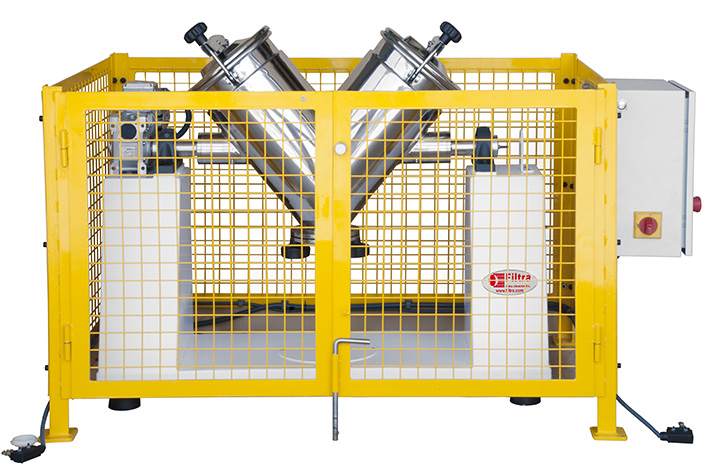

- Two machined and perfectly aligned supports on which to fix the rotational mountings holding the “V”.

- Gear motor drive.

- Drive transmission via geared coupling plates and bearings suitably protected against dust.

- Automatic stop positioner via detecting cells to stop loading and unloading.

- User manual.

- CE declaration of conformity.

OPTIONAL EQUIPMENT:

- Perfectly aligned intensifying bar with friction seals to repel dust, operated by electric motor.

- Covered safety protection barriers, or via detecting cells.

- Industrial V-Mixer have differents finishes and qualities.

| MODEL | Digital Timer | Voltage (Vac) |

Freq. (Hz) |

Mixer Power (kW) |

Intensifying Power (kW) | Useful Volume (L) |

|---|---|---|---|---|---|---|

| FTIMV-16 /i | 0 – 90 min | 230 (1F) | 50 | 0,25 | 0,55 | 8 |

| FTIMV-25 /i | 0,35 | 0,75 | 12,5 | |||

| FTIMV-50 /i | 400 (3F) | 0,55 | 1,1 | 25 | ||

| FTIMV-75 /i | 0,75 | 1,5 | 37,5 | |||

| FTIMV-100 /i | 1,1 | 2,2 | 100 | |||

| FTIMV-250 /i | 2,2 | 3 | 125 |

- Flours

- Pigments

- Glass

- Plastic

- Pesticides

- Herbicides

- Fertilizers

- Polymerized

- Pharmaceutical products

- Chemical products